Abstract:ADX-600 yog cov tub ntxhais-plhaub acrylic cuam tshuam hloov pauv resin (AIM) tsim los ntawm emulsion polymerization los ntawm peb lub tuam txhab.Cov khoom tuaj yeem ua tus hloov pauv rau PVC.ADX-600 AIM tuaj yeem hloov CPE thiab MBS raws li kev sib piv ntawm ntau qhov kev ua tau zoo ntawm AIM thiab cov khoom sib txawv PVC cuam tshuam.Cov khoom siv PVC ua rau pom cov khoom siv zoo heev, kev ua haujlwm zoo thiab kev ua haujlwm zoo dua.

Lo lus tseem ceeb:AIM, CPE, MBS, cuam tshuam kev hloov pauv, cov khoom siv kho tshuab

Taw qhia

PVC ua hauj lwm raws li universal yas nrog qhov loj tshaj plaws yield thiab daim ntawv thov dav nyob rau hauv lub ntiaj teb no.Nws tau siv dav hauv cov khoom xws li cov khoom siv hauv tsev, cov khoom lag luam, cov kav dej siv txhua hnub, cov ntaub ntawv sib khi, cov fibers, thiab lwm yam. PVC ua kom pom ntau yam zoo heev rau kev siv dav hauv ob qho tib si hauv kev lag luam thiab pej xeem.Txawm li cas los xij, PVC resin belongs rau cov ntaub ntawv nkig.Nws cov iav txuas ntxiv tsis tuaj yeem tiv thaiv qhov kev nthuav dav ntawm cov kab nrib pleb hauv kev ntxhov siab thiab thaum kawg ua qhov khoob thiab tawg tawg.Yog li ntawd, cov khoom zoo li no qhia txog kev cuam tshuam tsis zoo.Txawm li cas los xij, qhov tsis txaus no tuaj yeem kov yeej los ntawm kev ntxiv cov khoom hloov pauv rau hauv PVC cov ntaub ntawv thaum lawv tsim thiab molding txheej txheem.

Cov kev hloov pauv zoo yuav tsum tau ua los ntawm cov khoom zoo hauv qab no:

(1) Qhov kub tsis tshua muaj vitrification Tg;

(2) Kev sib raug zoo ntawm kev hloov pauv nws tus kheej nrog PVC cob;

(3) viscosity txuam ntawm kev hloov pauv nrog PVC;

(4) Tsis muaj qhov cuam tshuam tsis zoo rau qhov pom tseeb thiab lub cev thiab lub zog ntawm PVC;

(5) Kev tiv thaiv huab cua zoo thiab tuag o khoom.

Cov kev hloov pauv feem ntau rau cov tawv PVC feem ntau suav nrog chlorinated polyethylene (CPE), acrylate (ACR), ethylene-vinyl acetate copolymer (EVA), methyl methacrylate-butadiene-styrene ternary graft copolymer (MBS) thiab acrylonitrile-butadiene-styrene (ABS) ).Ntawm lawv, chlorinated polyethylene cuam tshuam kev hloov pauv tau siv dav hauv Suav teb thiab acrylate tseem tau txais yuav ntau ntxiv vim nws cov khoom zoo heev.Nws tau dhau los ua kev txhawj xeeb dav dav yuav ua li cas txhawm rau txhim kho qhov cuam tshuam thiab ua kom yooj yim rau extrusion ntawm yas.

Peb cov khoom AIM ADX-600 tuaj yeem hloov CPE thiab MBS.Nws tuaj yeem txhim kho fluidity thiab thermal deformation ntawm PVC yaj thiab yog li pab txhawb PVC yas.Cov khoom tshwm sim qhia tau hais tias muaj kev cuam tshuam rau lub zog thiab huab cua zoo, ruaj khov thiab ua cov cuab yeej nrog du, zoo nkauj thiab glossy nto.Tom ntej no, peb tau txheeb xyuas ACR, CPE thiab MBS hauv cov hauv qab no.

I. Mechanism of Toughening by PVC Impact Modifiers

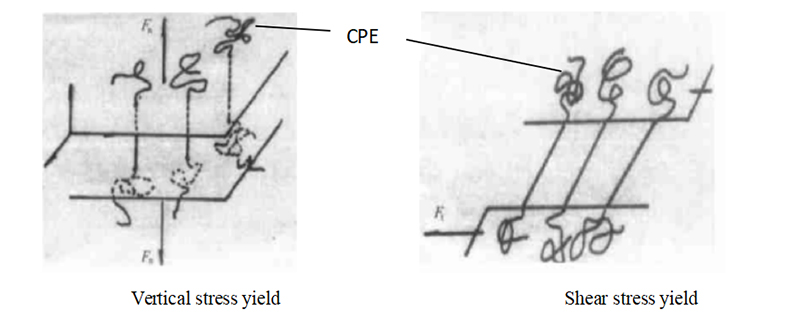

Chlorinated polyethylene (CPE) ua hauj lwm raws li linear molecules dispersed nyob rau hauv PVC matrix nyob rau hauv ib tug network daim ntawv.Lub hauv paus ntsiab lus ntawm kev cuam tshuam tsis kam yog tsim kom muaj kev sib txuas hauv cov khoom siv hauv PVC matrix thiaj li tiv thaiv kev cuam tshuam sab nraud.Xws li ib tug network yog nquag deform nyob rau hauv tensile quab yuam.Qhov no yuav ua rau lub shear plam ntawm qhov sib tov ntawm lub kaum sab xis ntawm 30 ° txog 45 ° los ntawm kev taw qhia tensile, yog li tsim cov shear band, absorbing ib tug loj npaum li cas ntawm deformation zog, thiab txhim khu lub tenacity ntawm blend system.Cov kev hloov pauv hauv kev ntxhov siab ntawm cov khoom siv nyob rau hauv lub zog sab nraud yog qhia hauv cov duab hauv qab no.

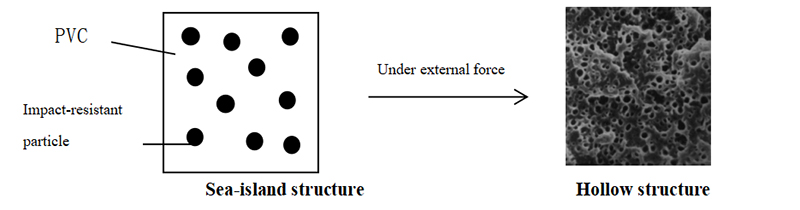

ACR thiab MBS yog ib hom "core-plhaub" copolymer cuam tshuam hloov pauv.Nws cov tub ntxhais ua haujlwm raws li tus ntoo khaub lig-txuas elastomer, uas ua lub luag haujlwm tseem ceeb hauv kev txhim kho tenacity thiab cuam tshuam.Nws lub plhaub ua haujlwm zoo li cov khoom siv polymer uas muaj qhov kub thiab txias dua, uas ua lub luag haujlwm tseem ceeb hauv kev tiv thaiv cov tub ntxhais roj hmab thiab txhim kho kev sib raug zoo nrog PVC.Hom kev hloov pauv no yooj yim rau kev sib cais thiab tuaj yeem sib npaug sib npaug rau hauv PVC matrix thiaj li tsim cov qauv "sea-kos".Thaum cov khoom raug cuam tshuam rau sab nraud, cov khoom siv roj hmab uas tsis tshua muaj modulus yog qhov ua rau deformation.Nyob rau tib lub sij hawm, de-bonding thiab kab noj hniav yog tsim raws li cov khoom yog tsav los ntawm PVC deformation nrog ib tug siab modulus.Yog tias cov qhov tau tsim ze txaus, cov txheej txheem matrix ntawm cov khoom siv roj hmab tuaj yeem tawm los thiab txhim kho lub zog ntawm cov khoom.Lub hauv paus ntsiab lus cuam tshuam-resistant yog qhia hauv daim duab hauv qab no.

CPE, ACR thiab MBS qhia qhov sib txawv rhiab heev rau machining zog vim lawv ntau yam toughening mechanism.Thaum lub sij hawm ua, ACR thiab MBS hais yog muab faib rau hauv PVC matrix los ntawm shearing txiav txim, tsim ib tug "sea-kob" qauv thiab yog li pab txhawb tenacity ntawm cov khoom.Txawm hais tias kev ua kom muaj zog ntxiv ntxiv, cov qauv no yuav tsis raug cuam tshuam yooj yim.Qhov zoo tshaj plaws toughening nyhuv tsuas yog ua kom tiav raws li CPE hloov kho thiab PVC yog sib tov rau hauv ib lub network qauv uas enfolds thawj PVC hais.Txawm li cas los xij, cov qauv network no tuaj yeem cuam tshuam tau yooj yim vim muaj kev hloov pauv hauv kev siv zog.Yog li ntawd, nws yog rhiab heev rau kev siv zog thiab siv rau ib tug nqaim ua ntau yam.

II.Kev sib piv ntawm Ntau Yam Khoom ntawm ADX-600 AIM thiab Txawv PVC Impact Modifiers

1. Cov qauv ntsuas cov khoom siv hauv paus

| Lub npe | Organo-tin Thaum tshav kub kub Stabilizer (HTM2010) | Calcium Stearate | Titanium Dioxide | PEB-6A | 312 | Calcium Carbonate | PVC-1000 Nws |

| Dosage/g | 2.0 | 0.7 ua | 4.0 | 0.6 | 0.2 | 5.0 | 100.0 |

2. Cov khoom cuam tshuam

| Cov khoom | Cov npe | Cov qauv xeem | Chav tsev | Additive Nyiaj (phr) | |||||

| 3 | 4 | 5 | 6 | 7 | 8 | ||||

| Kev cuam tshuam los ntawm Notched Cantilever Beam | TX-600 | ASTM D256 | KJ/m2 | 5.44 ib | 6.30 Nws | 7.78 ib | 8.72 ib | 9.92 ib | 12.02 Nws |

| ACR Los Ntawm Lub Tebchaws Txawv Tebchaws | KJ/m2 | 4.62 ib | 5.01 Nws | 7.68 ib | 8.51 ib | 9.63 ib | 11.85 Nws | ||

| MBS | KJ/m2 | 5.32 ib | 5.39 ib | 7.52 ib | 8.68 ib | 9.78 ib | 11.99 Nws | ||

| CPE | KJ/m2 | 3.54 ib | 4.25 ib | 5.39 ib | 6.32 ib | 7.01 Nws | 8.52 ib | ||

| Kev cuam tshuam los ntawm Notch-dawb Cantilever Beam | TX-600 | J/m | 57.03 ib | 63.87 ib | 72.79 ib | 88.23 ib | 100.09 Nws | 121.32 Nws | |

| ACR Los Ntawm Lub Tebchaws Txawv Tebchaws | J/m | 46.31 Nws | 50.65 ib | 72.55 ib | 85.87 ib | 97.92 ib | 119.25 Nws | ||

| MBS | J/m | 53.01 Nws | 62.07 Nws | 71.09 ib | 87.84 ib | 99.86 ib | 120.89 Nws | ||

| CPE | J/m | 21.08 Nws | 37.21 Nws | 47.59 ib | 59.24 ib | 70.32 ib | 82.21 ib | ||

3. Stretching / Bending Properties (Txhua tus nqi ntxiv yog 6phr)

| Cov khoom | Cov qauv xeem | Chav tsev | Technical Indicators (ADX-600) | Technical Indicators (ACR Los Ntawm Lub Tebchaws Txawv Tebchaws) | Technical Indicators (MBS) | Technical Indicators (CPE) |

| Tensile Elasticity Modulus | ASTM D 638 Cov | MPa | 2546.38 ib | 2565.35 Nws | 2500.31 Nws | 2687.21 ib |

| Tensile Elongation Yield | ASTM D 638 Cov | % | 28.38 Nws | 27.98 Nws | 26.84 Nws | 17.69 Nws |

| Tensile zog | ASTM D 638 Cov | MPa | 43.83 ib | 43.62 ib | 40.89 ib | 49.89 ib |

| Khoov Modulus | ASTM D 790 Cov Lus Qhia Tshwj Xeeb | MPa | 2561.11 Nws | 2509.30 Nws | 2528.69 ib | 2678.29 ib |

| Khoov zog | ASTM D 790 Cov Lus Qhia Tshwj Xeeb | MPa | 67.39 ib | 65.03 ib | 66.20 Nws | 69.27 ib |

Kev tsom xam: Raws li cov ntaub ntawv saum toj no ntawm cov khoom siv kho tshuab:

① Raws li tib koob tshuaj, kev ua tau zoo ntawm peb cov khoom ADX-600 zoo dua li ntawm MBS thiab ACR cov khoom lag luam los ntawm txawv teb chaws.Peb cov khoom tuaj yeem hloov tau lawv qhov sib npaug.

② Raws li tib koob tshuaj, kev ua tau zoo ntawm peb cov khoom ADX-600 yog siab dua li ntawm CPE.Raws li ntau qhov kev sim, nws tau raug txheeb xyuas tias 3 koob tshuaj ADX-600 ntxiv rau 3 koob tshuaj CPE tuaj yeem hloov pauv kev siv 9 koob tshuaj CPE.Cov yam ntxwv tshwj xeeb yog qhia raws li hauv qab no.

| Cov khoom | Cov qauv xeem | Chav tsev | Technical Indicators (ADX-600/3phr+CPE/3phr) | Technical Indicators (CPE/9phr) |

| Kev cuam tshuam los ntawm Notched Cantilever Beam | ASTM D256 | KJ/m2 | 9.92 ib | 9.86 ib |

| Kev cuam tshuam los ntawm Notch-dawb Cantilever Beam | ASTM D256 | J/m | 97.32 ib | 96.98 ib |

| Tensile Elasticity Modulus | ASTM D 638 Cov | MPa | 2250.96 Nws | 2230.14 Nws |

| Tensile Elongation Yield | ASTM D 638 Cov | % | 101.25 Nws | 100.24 Nws |

| Tensile zog | ASTM D 638 Cov | MPa | 34.87 ib | 34.25 Nws |

| Khoov Modulus | ASTM D 790 Cov Lus Qhia Tshwj Xeeb | MPa | 2203.54 Nws | 2200.01 Nws |

| Khoov zog | ASTM D 790 Cov Lus Qhia Tshwj Xeeb | MPa | 60.96 ib | 60.05 Nws |

4. Kev Ua Haujlwm

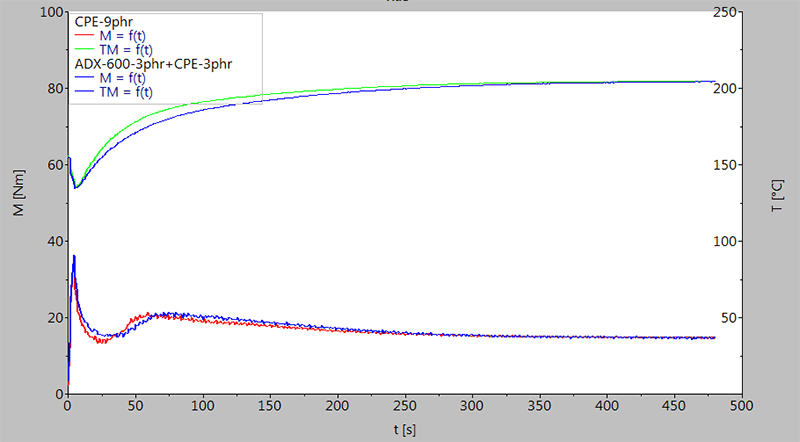

Daim duab hauv qab no qhia txog rheological nkhaus.Cov kab liab: ADX-600 / 3phr + CPE / 3phr;kab xiav: CPE / 9phr

Qhov sib npaug torques ntawm ob lub hauv paus yog tib yam, thiab lub plastification ntawm cov khoom hloov kho los ntawm ADX-600 / 3PHr + CPE / 3PHR yog qeeb me ntsis tab sis nyob rau hauv kev tswj raws li daim duab.Yog li ntawd, nyob rau hauv cov nqe lus ntawm kev ua, 3 koob tshuaj ADX-600 ntxiv rau 3 koob tshuaj CPE tuaj yeem hloov qhov kev siv ntawm 9 koob tshuaj CPE.

III.Cov lus xaus

Los ntawm kev sib piv ntawm ADX-600 AIM thiab CPE thiab MBS hauv cov khoom siv kho tshuab thiab kev coj tus cwj pwm, cov lus xaus hauv qab no tau raug kos los ntawm lub hom phiaj tsom xam tias 3 koob tshuaj ADX-600 ntxiv rau 3 koob tshuaj CPE tuaj yeem hloov pauv kev siv 9 koob tshuaj CPE. .ADX-600 AIM qhia tau hais tias kev ua tau zoo dua, uas cov khoom lag luam pom tau zoo dua thiab ua haujlwm tau zoo dua.

ADC-600 AIM belongs rau ib qho acrylate copolymer nrog core-plhaub qauv.ACR qhia txog huab cua zoo dua, kev ruaj ntseg kub thiab kev ua haujlwm-tus nqi piv dua li MBS vim tias yav dhau los tsis muaj ob daim ntawv cog lus.Tsis tas li ntawd, ACR kuj qhia txog qhov zoo ntawm kev ua ntau yam, ceev extrusion ceev, tswj tau yooj yim, thiab lwm yam. Nws yog tsuas yog siv rau hauv cov khoom siv tawv thiab semi-hard PVC, tshwj xeeb tshaj yog rau cov khoom siv hauv tsev thiab cov khoom siv sab nraum zoov, xws li profiles, kav, yeeb nkab fittings, boards, foaming cov ntaub ntawv, thiab lwm yam. Nws ua hauj lwm pab raws li ib yam ntawm cov kev hloov pauv nrog loj npaum li cas tam sim no thiab loj loj hlob tej zaum nyob rau hauv lub neej yav tom ntej.

Post lub sij hawm: Jun-20-2022