Lubricating Processing Aid ADX-201A

Khoom nta

1. ADX-201A tsis tshua muaj kev cuam tshuam rau kev ua haujlwm ntawm tus cwj pwm thiab qhov pib tsis ua rau lub zog nce ntxiv.

2. Cov cuab yeej zoo demoulding, siab pob tshab, ADX-201A tuaj yeem siv rau cov khoom pob tshab siab.

3. ADX-201A tuaj yeem tswj tau lub phaj-tawm ntawm kev tuag thiab ncua sij hawm ntau lawm.

Lub cev khoom

| Khoom | Index | Chav tsev |

| Qhov tshwm sim | Dawb hmoov | |

| Loj | 0.3-0.5 hli | g/cm3 |

| Volatile teeb meem | <1.5 | % |

| Intrinsic Viscosity | 0.7-0.9 hli | |

| 30 Mesh kuaj | >99 | % |

* Qhov ntsuas tsuas yog sawv cev rau cov txiaj ntsig zoo uas tsis suav tias yog qhov tshwj xeeb.

Piv txwv ntawm Formula Siv

| Lub npe | PVC-1000 Nws | PVC Thaum tshav kub kub Stabilizer(HTM 2010) | ADX-201 UA |

| Kev sib tw / g | 100.0 | 2.0 | |

| Test Sample/g | 100.0 | 2.0 | 0.5 |

Demoulding Performance

| Lub npe | Sijhawm | Kev tshwm sim |

| Kev sib tw | 15 | Cov ntaub ntawv lo rau cov menyuam hauv 1 min |

| Kuaj Qauv | 15 | Cov ntaub ntawv tsis lo rau cov menyuam hauv 20mins |

Piv txwv ntawm Formula Siv

| Lub npe | Ca Zn Stabilizer | PE Wax | Calcium Carbonate | ACR | TiO2 | PVC | ADX-201 UA |

| Kev sib tw / g | 1.3 | 1 | 0.3 | 0.5 | 1.5 | 100 | |

| Test Sample/g | 1.3 | 1 | 0.3 | 0.5 | 1.5 | 100 | 1 |

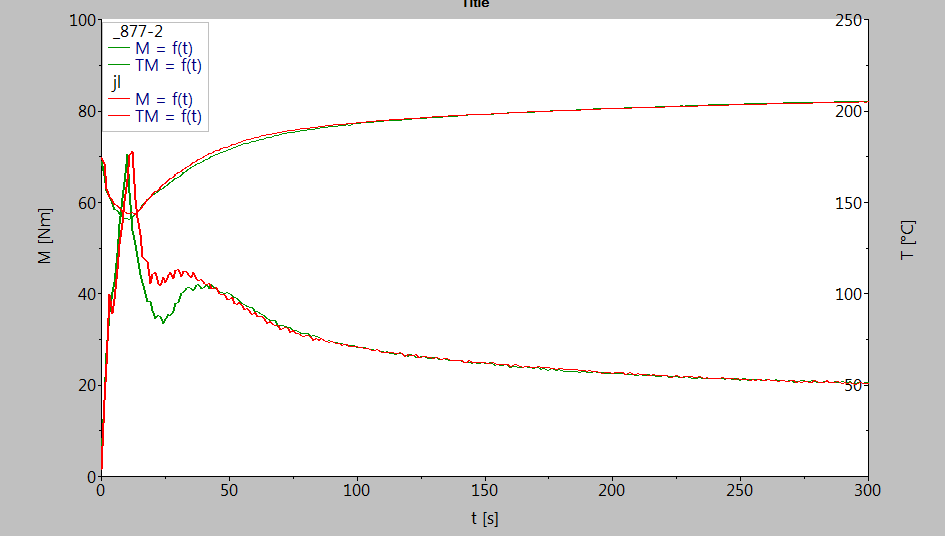

Rheology

Ntsuab nkhaus: Test qauv

Liab nkhaus: Kev sib tw